Car Wash Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SS Soap and Wax plumbing

- Thread starter AllStar Auto and Pet Wash

- Start date

AllStar Auto and Pet Wash

New member

I will give that a try, thanks! Where do you plumb these in to your system, curious

AllStar Auto and Pet Wash

New member

2Biz

Thread Killer!

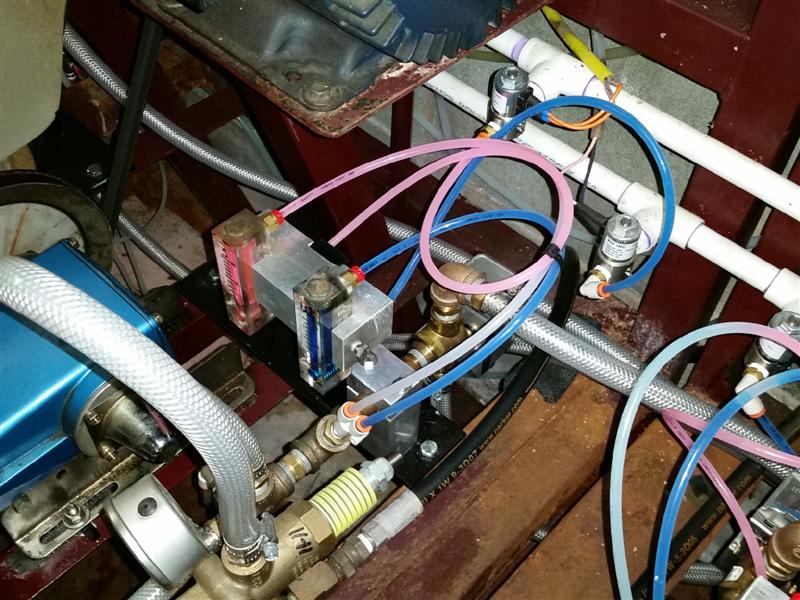

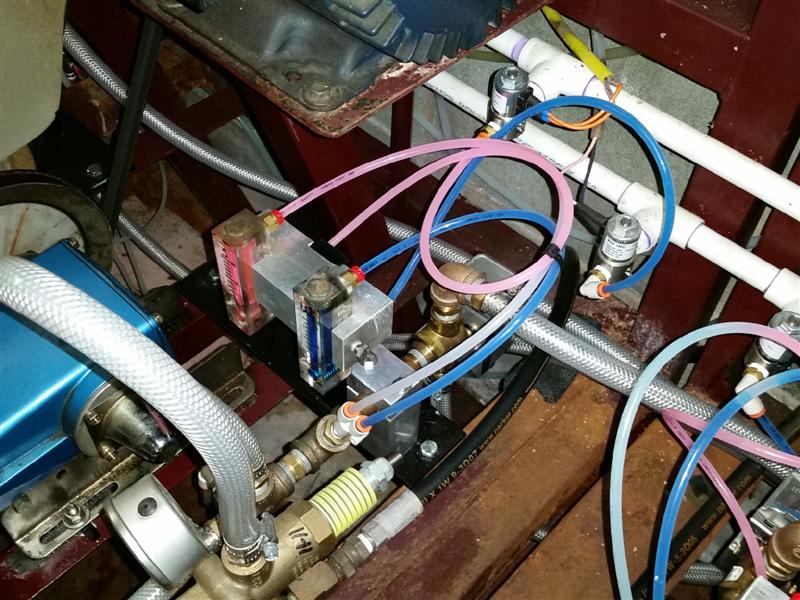

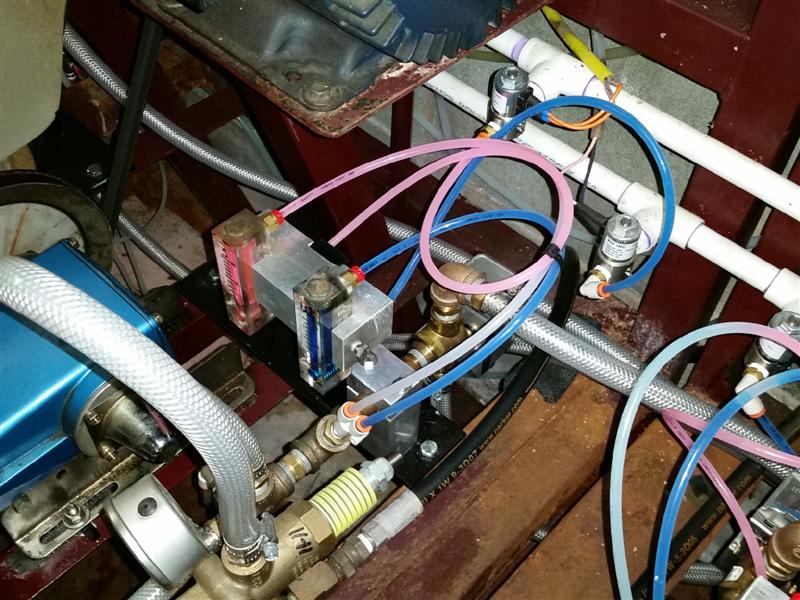

Here's a pic of how I have mine plumbed. BTW, its important to know my system is plumbed using gravity feed hot and cold water supply. I don't know that it matters much as long as the soap and wax are plumbed to the water inlet to the pump, this is just how I set mine up...I don't have any flow valves installed to restrict flow to get soap and wax to feed...Never a pump cavitation issue...The 1/2" fittings in the supply hose creates just enough vacuum to draw chemicals.

AllStar Auto and Pet Wash

New member

That's exactly how I have mine plumbed now and I also have gravity fed water. But I had to cut the ball valves back a lot more then I thought I would!Actually I'm on the cusp of cavitation but it's working great!Here's a pic of how I have mine plumbed. BTW, its important to know my system is plumbed using gravity feed hot and cold water supply. I don't know that it matters much as long as the soap and wax are plumbed to the water inlet to the pump, this is just how I set mine up...I don't have any flow valves installed to restrict flow to get soap and wax to feed...Never a pump cavitation issue...The 1/2" fittings in the supply hose creates just enough vacuum to draw chemicals.

Thanks for everyone's help!

MEP001

Well-known member

I use 1/2" hose to feed the pump from the tank, with this check valve on the line:

www.kleen-ritecorp.com

It creates some restriction, not enough to cause any issues, and the way they go together there's no way for the spring or seal to come loose and cause the valve to jam like the SMC ones do. Anytime there's 3/4" hose and 3/4" check valve I end up restricting the flow with the ball valve. Why have bigger plumbing if you end up throttling it back to make it work?

www.kleen-ritecorp.com

It creates some restriction, not enough to cause any issues, and the way they go together there's no way for the spring or seal to come loose and cause the valve to jam like the SMC ones do. Anytime there's 3/4" hose and 3/4" check valve I end up restricting the flow with the ball valve. Why have bigger plumbing if you end up throttling it back to make it work?

Kleen-Rite 944-430 | Brass Inline Check Valve | 1/2in. F x F

This resilient disc check valve is not lead free. It is not for use on potable applications.

AllStar Auto and Pet Wash

New member

That's a great idea, I'll give that a try! I only have 1/2" tubing as well but I always worry about the chance of the ball valves being moved.....

Thanks Again

Thanks Again