Car Wash Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

flojet vs procon pumps

- Thread starter mjc3333

- Start date

Since I have only two bays I would like to use one pump for each bay instead of presoak pump for two bays. the reason is I live right here and If I have trouble with a bay using presoak I can give money back give a free wash on other bay. So that would be my advantage to at least have one bay open.That's not how to do it. You could, theoretically, but it has no advantage over having a pump for each low pressure selection, and you would have really long changeover times. How is yours set up now?

A 1/3 HP motor is enough to max out the pressure of the pump I linked.

Sure you could probably do that, it'd take some doing but it could be done, but it won't be cheap.Since I have only two bays I would like to use one pump for each bay instead of presoak pump for two bays. the reason is I live right here and If I have trouble with a bay using presoak I can give money back give a free wash on other bay. So that would be my advantage to at least have one bay open.

MEP001

Well-known member

Then you might want to consider Flojet pumps with the quick-change mount instead. It takes me about 30 seconds to swap out a pump if it's not working. It takes me longer than that to open the changer to give a refund.Since I have only two bays I would like to use one pump for each bay instead of presoak pump for two bays. the reason is I live right here and If I have trouble with a bay using presoak I can give money back give a free wash on other bay. So that would be my advantage to at least have one bay open.

Like I said, you could do what you want with a Procon for each bay, but your customers won't like it, and you would still meed one dedicated for foam brush so you won't end up with fewer pumps.

Procon 1/2" pumps are listed as 240 gph

Flojet G57 are listed as 5-7 gpm

Tip size 2506 being the restriction on the wand shows a flojet @80 psi would still be restricted down below 5-7 gpm.

I also installed the flojet on a separate wand with 4040 and it needs more volume even when testing one bay. So I put on two G57's and it didn't look good enough.

I have been wanting to switch to procon on its own gun 4040 tip, but they are listed smaller volume by over half when comparing to a G57.

It looks to me like I need more volume then what either of these are capable of?

Flojet G57 are listed as 5-7 gpm

Tip size 2506 being the restriction on the wand shows a flojet @80 psi would still be restricted down below 5-7 gpm.

I also installed the flojet on a separate wand with 4040 and it needs more volume even when testing one bay. So I put on two G57's and it didn't look good enough.

I have been wanting to switch to procon on its own gun 4040 tip, but they are listed smaller volume by over half when comparing to a G57.

It looks to me like I need more volume then what either of these are capable of?

MEP001

Well-known member

What are you trying to do? Are you trying to get a good liquid-only pressure with a 4040 tip? The only time I've ever used or seen a 40 GPM rated tip in a self serve is on a foam gun, where most of what gets to the gun is foam. You should be able to run at least six bays at once with a G57 Flojet.Procon 1/2" pumps are listed as 240 gph

Flojet G57 are listed as 5-7 gpm

Tip size 2506 being the restriction on the wand shows a flojet @80 psi would still be restricted down below 5-7 gpm.

I also installed the flojet on a separate wand with 4040 and it needs more volume even when testing one bay. So I put on two G57's and it didn't look good enough.

I have been wanting to switch to procon on its own gun 4040 tip, but they are listed smaller volume by over half when comparing to a G57.

It looks to me like I need more volume then what either of these are capable of?

Looking for the foam cannon type of foaming.What are you trying to do? Are you trying to get a good liquid-only pressure with a 4040 tip? The only time I've ever used or seen a 40 GPM rated tip in a self serve is on a foam gun, where most of what gets to the gun is foam. You should be able to run at least six bays at once with a G57 Flojet.

When I hook up the foam style gun with the 4040tip and a g57 I wasn't impressed and now I see people are using the procon that has even less gpm.

Apparently I have a bottle neck in my system holding the flojet back that's not the 4040 tip.

mjc3333

Member

What model Procon pump is in the picture? Do you set the pressure within the pump, or do you rely on the pressure regulator connected to the solenoid bank?Here's a pic of my coleman stand like Mep was referring to

MEP001

Well-known member

What model Procon pump is in the picture? Do you set the pressure within the pump, or do you rely on the pressure regulator connected to the solenoid bank?

Procon Rotary Pump Clamp Style; Brass Body

THE BEST PRICE ON Procon Rotary Pump Clamp Style; Brass Body

MEP001

Well-known member

You need a pressure washer and a foam cannon. You won't get foam cannon foam from 90 PSI liquid.Looking for the foam cannon type of foaming.

MEP001

Well-known member

Yes, but it won't go much lower. I recommend you take the cap off with the pump off, back the adjuster out until it's held in by at least a full thread, then turn it on and adjust it in/up until you reach the pressure you want. I've seen someone back it out too far and had all the valve parts shoot out the opening when they loosened the adjuster too far out.

mjc3333

Member

Got it.Yes, but it won't go much lower. I recommend you take the cap off with the pump off, back the adjuster out until it's held in by at least a full thread, then turn it on and adjust it in/up until you reach the pressure you want. I've seen someone back it out too far and had all the valve parts shoot out the opening when they loosened the adjuster too far out.

2Biz

Thread Killer!

Looking for the foam cannon type of foaming.

When I hook up the foam style gun with the 4040tip and a g57 I wasn't impressed and now I see people are using the procon that has even less gpm.

Apparently I have a bottle neck in my system holding the flojet back that's not the 4040 tip.

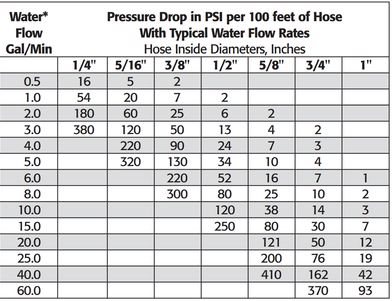

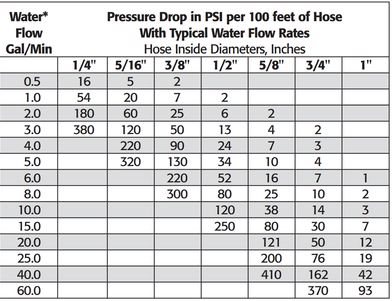

If you're using 1/4" tubing to the bays, that will be your bottleneck, try using 3/8". You'll get the same flow at 8 times less pressure. Same as being able to get 8 times more flow at the same pressure. A flojet has more than enough volume, but the tubing has to be sized correctly out from the flojet or even a procon.

Last edited:

We just moved the TC & PS to dispense out of the Tri foam gun utilizing the existing 1/4 poly tubing. We used a flow jet g57 pump and the existing 5040 trifoam tips. Were are getting great coverage and lots of positive feedback. 2Biz, I don't understand how you came to the conclusion that "You'll get the same flow at 8 times less pressure" from the attached table?If you're using 1/4" tubing to the bays, that will be your bottleneck, try using 3/8". You'll get the same flow at 8 times less pressure. Same as being able to get 8 times more flow at the same pressure. A flojet has more than enough volume, but the tubing has to be sized correctly out from the flojet or even a procon.