This is how it should look:

The clear point the left arrow is pointing to is what actually pushes the dial to start the regeneration cycle. This is yours:

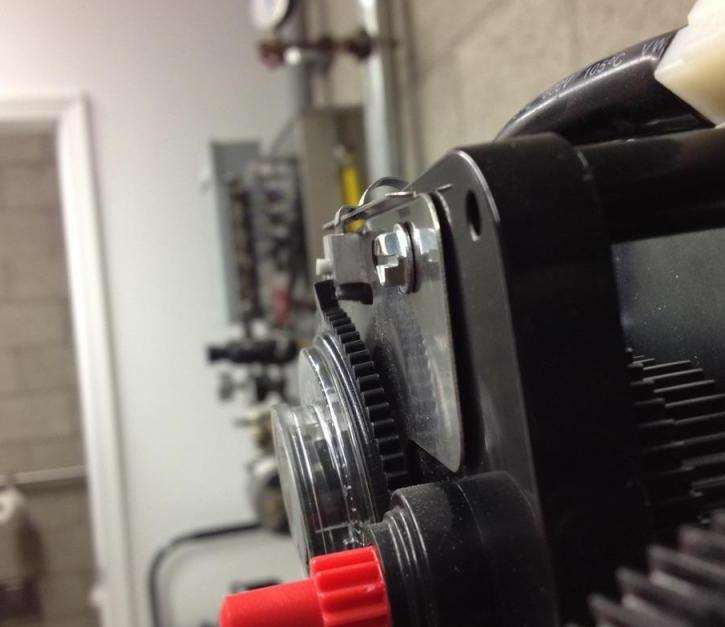

The point is quite clearly past the dial and it should never have gotten that far. Now look at this image again:

The metal plate is either loose or bent - it should always lay flat against the plastic.

First, see if you can lift the plate up and spin the meter dial counter-clockwise a few turns to get the spring pressure back on it. I'd suggest unplugging the softener and turning the regen dial to let the point clear. If the meter dial seems loose where you can pull it away from the back plate, take a pocket knife and lift off the metal disk in the center so you can tighten the screw in the center. Don't bear down on anything, it should just be easily snug. If that all goes well, tighten the screw that holds the metal plate down - it appears to be too loose. Tighten it just enough where the plate still moves up with no friction.

If none of that works like it should, the timer

door is very easy to replace. Just remove the screw that the

door hinges on that has the ground wire on it, tilt it out and unplug the harness.

As far as it not regenerating at the correct gallon uses, I can tell you what it should be set for if you measure the height and diameter of the tanks. It looks like you have it as high as it will go, and if that isn't high enough you'll need an extended range meter and dial.