Kimberly Berg

Well-known member

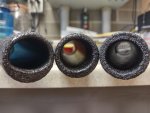

4 year ago we installed Diskin's Air Shammee II in our 5-bay SS wash. I'm NOT a big fan of their guns, nothing but problems...

- Gun rivets are too short & back themselves out. Now we use longer "Butterfly" rivets

- Hose unscrewing out of the "swivel nut". Now we use JB Weld (plastic glue) to glue the hose into the swivel nut

- Gun trigger sticking or disintegrating (due to plastic incompatibility)

Anyone else having problems? I've talked to Troy Diskin, but he seems indifferent to my problems or solutions.

Today, I think I found the solution! I had purchased an Air Logic gun from Kleen-Rite (Part # AD2000) to try out. This morning, I replaced a Diskin gun with the Air Logic. Already, I LIKE IT BETTER! No rivets to fall out, no trigger to stick AND I think it puts out MORE AIR, since there's no plastic baffle inside the gun.

- Gun rivets are too short & back themselves out. Now we use longer "Butterfly" rivets

- Hose unscrewing out of the "swivel nut". Now we use JB Weld (plastic glue) to glue the hose into the swivel nut

- Gun trigger sticking or disintegrating (due to plastic incompatibility)

Anyone else having problems? I've talked to Troy Diskin, but he seems indifferent to my problems or solutions.

Today, I think I found the solution! I had purchased an Air Logic gun from Kleen-Rite (Part # AD2000) to try out. This morning, I replaced a Diskin gun with the Air Logic. Already, I LIKE IT BETTER! No rivets to fall out, no trigger to stick AND I think it puts out MORE AIR, since there's no plastic baffle inside the gun.