Big K

New member

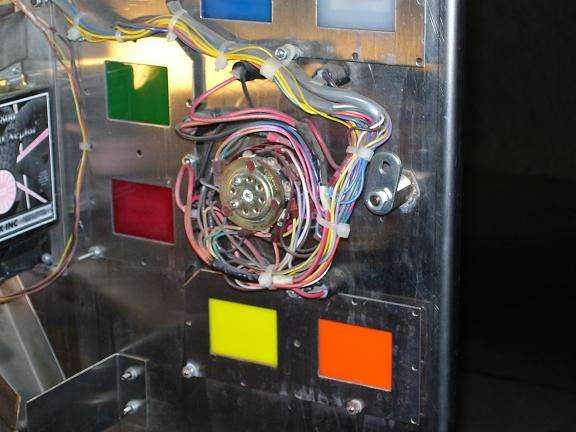

I am hoping someone can provide some wisdom to a vac problem that really has me stumped

Problem: The vac will not turn on after coins are dropped.

Here's where the fun started...

I verified that current was at the two motors and learned that current was detected all over the IDX box and the switch at the coin acceptor (Unit A). Next I moved the motors, IDX box (timer), and the coin acceptor over to another exact same unit (Unit B).

After the components from Unit A were in Unit B, Unit B worked like a charm. However, the Unit B components when installed in Unit A exhibit the same problem with current being detected at the motors, IDX box (timer), and coin acceptor and not turning on. There is no current detected on the unit housing or anywhere else?

Any wisdom on this dilemma would be much appriciated !

Problem: The vac will not turn on after coins are dropped.

Here's where the fun started...

I verified that current was at the two motors and learned that current was detected all over the IDX box and the switch at the coin acceptor (Unit A). Next I moved the motors, IDX box (timer), and the coin acceptor over to another exact same unit (Unit B).

After the components from Unit A were in Unit B, Unit B worked like a charm. However, the Unit B components when installed in Unit A exhibit the same problem with current being detected at the motors, IDX box (timer), and coin acceptor and not turning on. There is no current detected on the unit housing or anywhere else?

Any wisdom on this dilemma would be much appriciated !