Big Chris

New member

So I bought a Super Wash site in April, and this is my first winter with it. Last night the temps fell to 18°F. I've got a question regarding my slab heat.

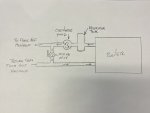

Please take a look at the diagram below.

Before I started messing with it, my attendant complained the floor heat never worked well, and he spent alot of time "chopping ice" last winter. When we tested it earlier this fall the natural gas boiler would run and cycle fine, but the pipe that ran to the floor heat manifold never really got warm. The mixing valve was wide open, but there was this sticker on the pipes next to the valve that reads " bypass valve 20% open". The sticker looks to be original. So I grabbed another ball valve I had laying around, and I "eyeballed" what 20% looked like (sighting down the bore of the valve) made a note of what the lever on the valve looked like and set the mixing valve to approximately this setting.

Wha-la, the pipe leading to the manifold instantly got warm, and I could eventually feel the return line from the floor no longer be "ice-cold". All was good with the world and after about 20 minutes or so I left for the night. This was on Monday. I should note that the pipe leading to the floor manifold doesn't get "hot" it gets warm......

Tuesday when I came in the circulator pump was running (indicating the slab thermostat was calling for heat) but the reservoir tank was ice cold, and the boiler wasn't on.... And the slab temp was approx 34°F. So I turned the system off and immediately back on and the boiler fired. So I sat and watched and waited and did some other chores. After 30 minutes of the boiler cycling (firing and shutting off), the boiler shut off and did not restart. Exactly 30 minutes. I retested. Same result at 30 minutes the boiler shut off even though the thermostat was calling for heat. That's strange, I thought.

During this time I made note that the boiler temp never got over 110°F (now that I changed the setting on the mixing valve). Then I had this eureka moment. The high limit was set to 180°F and the low was set to 140°F. Since the boiler never got to 140°F the system "timed out" and shut down after 30 min (this is my theory). So I set the low limit to 100°F. And now the system is working fine, and the floor heat worked flawlessly last night. Came in this morning (Wednesday) and the outside temp was 19°F and the floor is approx 38°F and everything seemed ok.

Sorry for the longwinded saga above but here's my question: Since the mixing valve was wide open and the fluid was just circulating through the boiler, the boiler was able to get to 140°F and not time out. Since I heeded the "bypass valve 20% open" sticker and then reset the low limit on the boiler my floor heat works. I can literally see stripes on the floor where the heat is melting ice, but is there something I am overlooking? Am I being inefficient? Am I way out in left field?

I am not a HVAC expert. I am not super familiar with these systems. Looking for advice here. Especially from another "Super Wash" site owner.

Thanks Chris

Please take a look at the diagram below.

Before I started messing with it, my attendant complained the floor heat never worked well, and he spent alot of time "chopping ice" last winter. When we tested it earlier this fall the natural gas boiler would run and cycle fine, but the pipe that ran to the floor heat manifold never really got warm. The mixing valve was wide open, but there was this sticker on the pipes next to the valve that reads " bypass valve 20% open". The sticker looks to be original. So I grabbed another ball valve I had laying around, and I "eyeballed" what 20% looked like (sighting down the bore of the valve) made a note of what the lever on the valve looked like and set the mixing valve to approximately this setting.

Wha-la, the pipe leading to the manifold instantly got warm, and I could eventually feel the return line from the floor no longer be "ice-cold". All was good with the world and after about 20 minutes or so I left for the night. This was on Monday. I should note that the pipe leading to the floor manifold doesn't get "hot" it gets warm......

Tuesday when I came in the circulator pump was running (indicating the slab thermostat was calling for heat) but the reservoir tank was ice cold, and the boiler wasn't on.... And the slab temp was approx 34°F. So I turned the system off and immediately back on and the boiler fired. So I sat and watched and waited and did some other chores. After 30 minutes of the boiler cycling (firing and shutting off), the boiler shut off and did not restart. Exactly 30 minutes. I retested. Same result at 30 minutes the boiler shut off even though the thermostat was calling for heat. That's strange, I thought.

During this time I made note that the boiler temp never got over 110°F (now that I changed the setting on the mixing valve). Then I had this eureka moment. The high limit was set to 180°F and the low was set to 140°F. Since the boiler never got to 140°F the system "timed out" and shut down after 30 min (this is my theory). So I set the low limit to 100°F. And now the system is working fine, and the floor heat worked flawlessly last night. Came in this morning (Wednesday) and the outside temp was 19°F and the floor is approx 38°F and everything seemed ok.

Sorry for the longwinded saga above but here's my question: Since the mixing valve was wide open and the fluid was just circulating through the boiler, the boiler was able to get to 140°F and not time out. Since I heeded the "bypass valve 20% open" sticker and then reset the low limit on the boiler my floor heat works. I can literally see stripes on the floor where the heat is melting ice, but is there something I am overlooking? Am I being inefficient? Am I way out in left field?

I am not a HVAC expert. I am not super familiar with these systems. Looking for advice here. Especially from another "Super Wash" site owner.

Thanks Chris

Last edited: