starion

7SS 2IBA

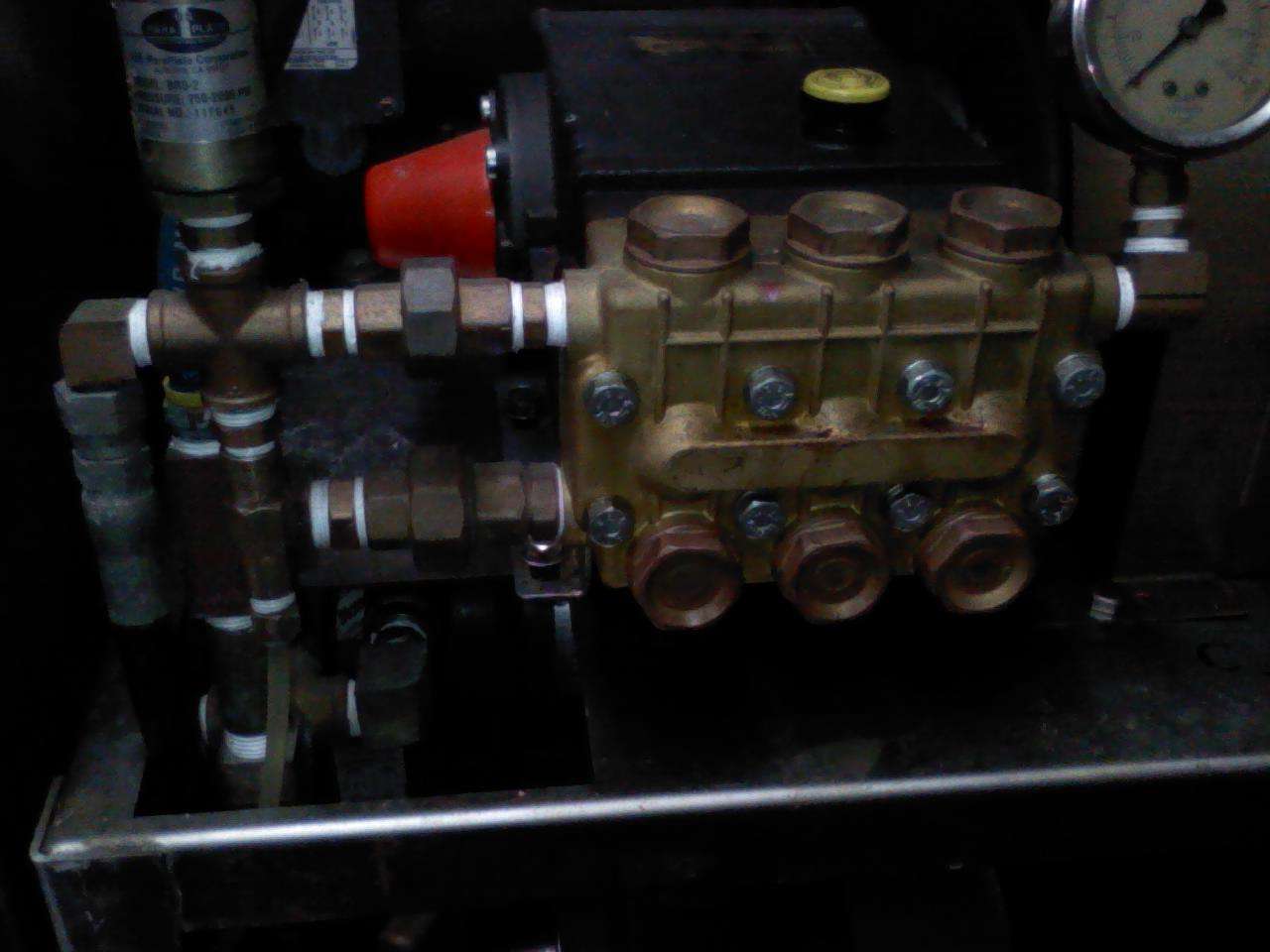

One of my HyPro 8GPM pumps on bay 2 had been leaking oil for a few months. Yesterday, it finally spewed oil all over the back of the motor and stand and came to a screeching halt.

I took apart all the connecting plumbing, got the pump out by itself and am contemplating a rebuild myself or just taking it somewhere. That's for another discussion however.

In looking at how things were configured, I wondered if there were a better a way to put the plumbing back together. I pretty much understand why things are where they are and their function, except for one thing.

The water input (the blue rubber hose on the left going behind the motor) is connected to (what I believe) is a zero-pressure injector (the saucer/diaphragm). The soap and wax are injected through the blue and red tube when switched on.

My question is this: what is the purpose of a zero-pressure injector and why could I not use a tree with two chemtronics injectors instead? I used the chemtronics on my automatic for chemical dispensing and they work GREAT.

Am I missing some theory of operation here? Is it simply the volume of water can't be passed by a "ball-spring" type of injector?

I took apart all the connecting plumbing, got the pump out by itself and am contemplating a rebuild myself or just taking it somewhere. That's for another discussion however.

In looking at how things were configured, I wondered if there were a better a way to put the plumbing back together. I pretty much understand why things are where they are and their function, except for one thing.

The water input (the blue rubber hose on the left going behind the motor) is connected to (what I believe) is a zero-pressure injector (the saucer/diaphragm). The soap and wax are injected through the blue and red tube when switched on.

My question is this: what is the purpose of a zero-pressure injector and why could I not use a tree with two chemtronics injectors instead? I used the chemtronics on my automatic for chemical dispensing and they work GREAT.

Am I missing some theory of operation here? Is it simply the volume of water can't be passed by a "ball-spring" type of injector?