Car Wash Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

high pressure tubing type

- Thread starter cmawash

- Start date

cantbreak80

Maybe I need new clubs

Ghetto Wash

Active member

If you're in an area that freezes and you ever have a freeze up, copper will stretch and you'll never get another fitting on it after that.

MEP001

Well-known member

That's a good point, but once the copper expands it'll be difficult to impossible to repair it if it does split. And copper (or cupronickel) erodes with a lot of water flow. Stainless tube won't.If you're in an area that freezes and you ever have a freeze up, copper will stretch and you'll never get another fitting on it after that.

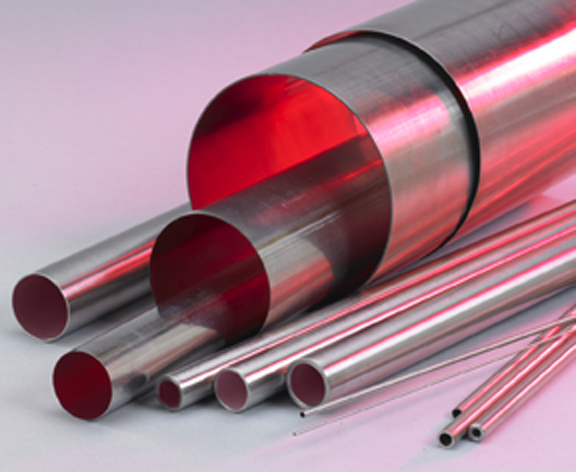

want to do job once and correctly so we never have to look at it againI always use 304L Stainless Welded Tubing .375 OD for high pressure bay supply.

Plan well because the stainless steel compression fittings will give you sticker shock!

However...it's unlikely that you'll ever have to replace the high pressure lines.

View attachment 2420

Here ya gowhat is is difference between SS seamless and SS welded tubing system operates around 2k psi

Welded vs Seamless Stainless Steel Tubing: What’s the Difference?

Welded and seamless stainless steel tubing each offer unique benefits depending on application. Learn which option might be best for your needs here...

mjwalsh

6 bay SS w/laundromat

Has anyone seen stainless steel be affected by a hard freeze?

Most long term "far enough north" or high elevation operators know about a hard freeze vs a milder freeze up of pipes. I noticed a local city worker preparing for this by vacuuming the upper part of fire hydrants about a week ago.

This article leads me to believe that stainless is better than copper but I am not so sure better than rubber hose for high pressure lines from ER:

Mechanics & Forces of Freezing Water, Effects of ice and freezing water on building plumbing systems (inspectapedia.com)

Most long term "far enough north" or high elevation operators know about a hard freeze vs a milder freeze up of pipes. I noticed a local city worker preparing for this by vacuuming the upper part of fire hydrants about a week ago.

This article leads me to believe that stainless is better than copper but I am not so sure better than rubber hose for high pressure lines from ER:

Mechanics & Forces of Freezing Water, Effects of ice and freezing water on building plumbing systems (inspectapedia.com)

cantbreak80

Maybe I need new clubs

Couple hundred bays of SS and IBAs in use in CO/WY/AK. I don't recall ever having to replace a freeze damaged tube.

An improperly bent tube?...well, that's another story. (Rookie!!!)

An improperly bent tube?...well, that's another story. (Rookie!!!)

mjwalsh

6 bay SS w/laundromat

Couple hundred bays of SS and IBAs in use in CO/WY/AK. I don't recall ever having to replace a freeze damaged tube.

An improperly bent tube?...well, that's another story. (Rookie!!!)

cantbreak80 & other stainless tubing operators,

I am thinking that if a hard freeze up did not do any damage ... that it is because the expansion force had somewhere to crawl to ... maybe an opening or the rubber hose in the bay or the path back into the ER ... I am not sure.

We had copper tubing at one time & because of the problems after unplanned freeze ups we went with hydraulic hose cut & made up to the needed lengths by a Specialty Equip crew out of the Mpls-St Paul area back in 1987. We always keep precut exact lengths just in case the rare burst in the 4" PVC occurs. If SS tubing would last for at least 15 years & no danger of freeze damage ... it very well might be worthwhile ... in spite of its possible extreme initial extra cost!? Care would have to be taken during the install to not have any potential chance of the tubing rubbing against each other or any other hard surface IMHO!

mjwalsh

6 bay SS w/laundromat

Has any other car wash operator who actually uses high pressure thermoplastic hose or tubing have had a worse case freezing of its water inside of it with no problems other than the need to thaw it out??? I notice there are items such as ultra high pressure thermoplastic hose ... I am thinking that specific type of thermoplastic hose &/or tube possibly might not be permanently damaged by a hard freeze.

MEP001

Well-known member

SS needs to be installed in a way that it can't rub on anything, and it would need a pulse dampener at the pump or it will vibrate and make a lot of noise. Thermoplastic gives with the pulsing of the pump and doesn't need a pulse dampener, and just needs to be protected from rubbing on corners that could wear through it.

cantbreak80

Maybe I need new clubs

I have local sources for SS tubing, SS fittings, Hydrazorb or Cush'n'Clamps, etc. But, it's a metro area...with many wholesale distributors.

One online source, with "reasonable" pricing is: StainlessSteelFittings.com

View post #3 photo to see how I install.

Inside the equipment room the tubing is connected to the pumps with 100/R1 hoses. I try to make the hoses equal length so only one spare is needed.

The tubing terminates inside the trough, above the boom. 100/R1 connects the SS to the boom. Again, with equal length hoses.

The installations do hum a bit (because they don't know the words? )...even with pulsation dampeners installed. But, unless a pump has issues, it's really not annoying.

)...even with pulsation dampeners installed. But, unless a pump has issues, it's really not annoying.

One online source, with "reasonable" pricing is: StainlessSteelFittings.com

View post #3 photo to see how I install.

Inside the equipment room the tubing is connected to the pumps with 100/R1 hoses. I try to make the hoses equal length so only one spare is needed.

The tubing terminates inside the trough, above the boom. 100/R1 connects the SS to the boom. Again, with equal length hoses.

The installations do hum a bit (because they don't know the words?

cantbreak80

Maybe I need new clubs

I've always used double ferrule compression for SS installations. Fast, simple, and trouble free.