cmawash

Member

planning on doing some upgrades, want to use ss x 3/8 tubing or copper nickel tubing. which on would be recommended to use

That's a good point, but once the copper expands it'll be difficult to impossible to repair it if it does split. And copper (or cupronickel) erodes with a lot of water flow. Stainless tube won't.If you're in an area that freezes and you ever have a freeze up, copper will stretch and you'll never get another fitting on it after that.

want to do job once and correctly so we never have to look at it againI always use 304L Stainless Welded Tubing .375 OD for high pressure bay supply.

Plan well because the stainless steel compression fittings will give you sticker shock!

However...it's unlikely that you'll ever have to replace the high pressure lines.

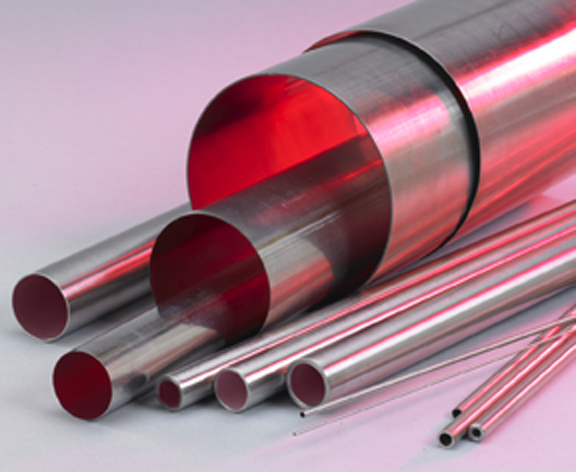

View attachment 2420

Here ya gowhat is is difference between SS seamless and SS welded tubing system operates around 2k psi

cantbreak80 & other stainless tubing operators,Couple hundred bays of SS and IBAs in use in CO/WY/AK. I don't recall ever having to replace a freeze damaged tube.

An improperly bent tube?...well, that's another story. (Rookie!!!)