I am using these to supply the liquid to my flojet:https://www.kleen-ritecorp.com/p-3432-flojet-20381063-poly-tube-fitting-12.aspx

I need a similar push fitting to supply the air to the pump, anyone know what I need? I can't find it on Kleenrite.

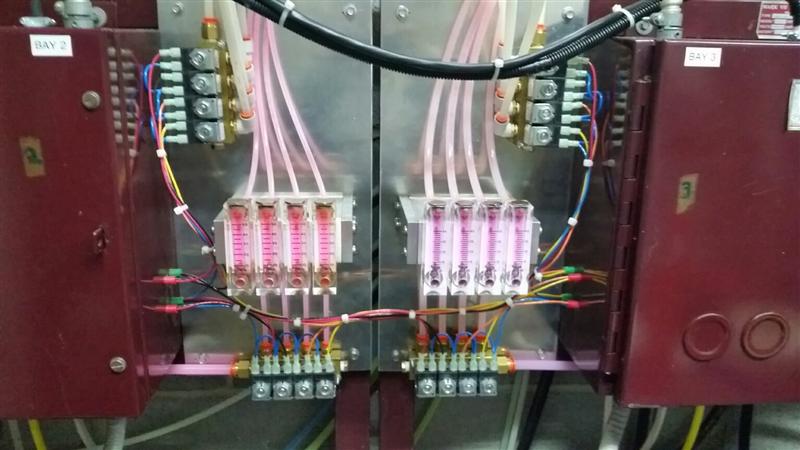

Also if I have 1/2" supplying the flojet shouldn't I have 1/2" supplying the solenoid block?:https://www.kleen-ritecorp.com/p-1968-kip-manifold-blocks-no-metering-3-outlets.aspx I need a 1/4" to 1/2" push fitting, but can't find it either.

I need a similar push fitting to supply the air to the pump, anyone know what I need? I can't find it on Kleenrite.

Also if I have 1/2" supplying the flojet shouldn't I have 1/2" supplying the solenoid block?:https://www.kleen-ritecorp.com/p-1968-kip-manifold-blocks-no-metering-3-outlets.aspx I need a 1/4" to 1/2" push fitting, but can't find it either.