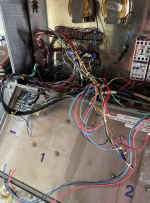

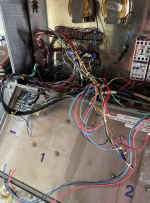

Hi I've been posting about a 5 SS - 1 IBA property I'm buying (linked here). I've been getting quotes from Petit and WW on new IBA and SS. I was leaning toward getting the old Carolina Pride equipment back up and running and just running new hoses, brushes, etc in the bays. THEN....some thieves broke in, stole all the wiring in the building and to the main, and cut and stole a bunch of the copper water supply lines. On top of that, they simply cut the wiring in the box for the ss equipment. Left it there, just cut it like @ssholes.

I spent a good amount of time there today and I think I can figure out how to get the wiring sorted and back the way it needs to be to power the SS and reuse the equipment without the $100k+ spend to get all new. I'd really love to do that. Here are some pictures of the wiring cabinet. I'd love any feedback about this plan. Honestly feel like I should give the current equipment every chance at working before ripping it out but I've also seen other sites that just installed new and their equipment room looks pretty darn good...

I spent a good amount of time there today and I think I can figure out how to get the wiring sorted and back the way it needs to be to power the SS and reuse the equipment without the $100k+ spend to get all new. I'd really love to do that. Here are some pictures of the wiring cabinet. I'd love any feedback about this plan. Honestly feel like I should give the current equipment every chance at working before ripping it out but I've also seen other sites that just installed new and their equipment room looks pretty darn good...