am86

New member

Hi everyone.

At our carwash site, we are using the Arimitsu 520 pumps on our bay stand for high pressure delivery. We are noticing we are only getting 6 months life out of our seal kits which are expensive and we don't know if its normal and if we are doing some different that is causing the premature failure.

We a delivering both unheated water and heated water. The maximum temperature the heated water could 85 degrees celcius (185 degrees farenheit). This is the reading on our hot water tank so inside pump it will be a unknown amount less but will sstill be high. Could this 185 degree liquid be a contributing factore to the seal life?

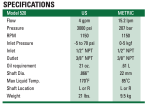

On the Armatsu 520 pump specifications it states that the max liquid temperature is 170 degrees farenheit and 85 degrees celcius, but this is clearly a mistake as 170 degrees farenheit is 76 degrees celcius. Do you think this incorrect specification is the cause of our equipment failure?

Any advice would be greatly appreciated.

Many thanks,

Alex

At our carwash site, we are using the Arimitsu 520 pumps on our bay stand for high pressure delivery. We are noticing we are only getting 6 months life out of our seal kits which are expensive and we don't know if its normal and if we are doing some different that is causing the premature failure.

We a delivering both unheated water and heated water. The maximum temperature the heated water could 85 degrees celcius (185 degrees farenheit). This is the reading on our hot water tank so inside pump it will be a unknown amount less but will sstill be high. Could this 185 degree liquid be a contributing factore to the seal life?

On the Armatsu 520 pump specifications it states that the max liquid temperature is 170 degrees farenheit and 85 degrees celcius, but this is clearly a mistake as 170 degrees farenheit is 76 degrees celcius. Do you think this incorrect specification is the cause of our equipment failure?

Any advice would be greatly appreciated.

Many thanks,

Alex

Last edited: